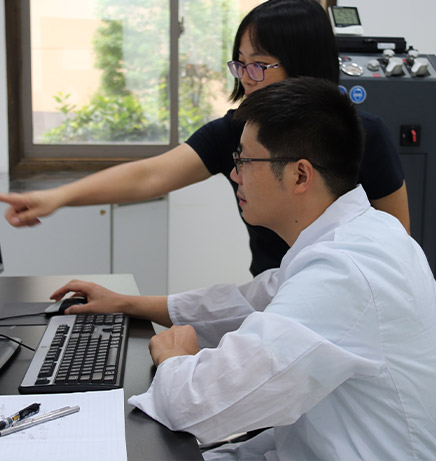

The Institute has set up an academician workstation and a post-doctoral workstation, owns leading scientific and technical talents of Shanghai, outstanding academic leaders and Rising-Star talents. It has over one hundred invention patents and utility model patents, and has undertaken more than ten Shanghai and national projects.

The institute is a member unit of Failure Analysis Institute of China Mechanical Engineering Society (CMES), and China Testing Machine Standardization Council, council member of China Industry-University-Research Cooperation Promotion Association. The Institute became qualified as a member of Failure Analysis Branch Institute of CMES in 2006; in 2010, Shanghai Engineering Research Center for Petroleum Tubular Goods was founded based on the Institute; in 2011, as affirmed by Shanghai Enterprise Technology Center in 2011, the inspection and testing center affiliated to the Institute became qualified by China National Accreditation Service for Conformity Assessment (CNAS) as accredited laboratories .

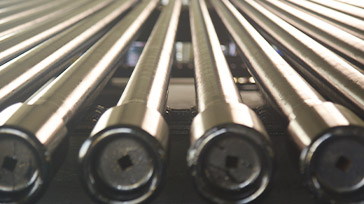

- Development of special drilling tools used in harsh service environment;

- Failure analysis and quality supervision for drilling tools;

- Welding technology research for pipelines, especially for composite steel pipes and offshore pipelines;

- inspection and testing of metallic materrials.

.jpg)

.jpg)

The Institute has established research cooperation and communication relationship with some research organizations, such as Fudan University, Tongji University, East China University of Science and Technology, Southwest Petroleum University, Shanghai University, Shanghai University of Science and Technology,Shanghai University of Engineering Science. Shanghai Material Research Institute, CNPC Tubular Goods Research Institute and Xi’an Moore Petroleum Engineering Research Institute. The Institute has founded a post-doctoral workstations, Hilong Scientific Research Base, by working with Southwest Petroleum University and Shanghai University; and has founded an Industry-University-Research Cooperation Achievements Application and Talents Cultivation base by associating with Shanghai University, under the leadership of Shanghai Science and technology commission.

Scan and follow us

Scan and follow us沪ICP备14040674号-1 沪公网安备 31011302005992号 © 2018 HI LONG GROUP OF COMPANIES, All Rights ReservedPrivacy Policy

沪公网安备 31011302005992号 © 2018 HI LONG GROUP OF COMPANIES, All Rights ReservedPrivacy Policy